Beer Sensory Skills 101 | Water | Chlorophenol

This article is part of a series of lessons and exercises that focus on enhancing your sensory skills to better recognize and address brewing problems. By training your sense of smell, taste, mouthfeel, etc., you will have a better understanding of identifying off-flavors/aromas and their causes, which can greatly assist you when looking for solutions to these problems. This blog series will come in many parts dealing with Yeast, Hops, Malt, Water, Infections/Contaminations, and Miscellaneous issues.

Each lesson includes an exercise in a separate tab to assist you in developing your palate and other senses to better detect these flavors, aromas, etc.

Lesson 4.1- Water: Chlorophenol - Chlorine is For Pools, Not Beers!

The Chemistry:

Water is the unsung hero of brewing, comprising a significant portion of beer's composition and influencing its flavor, aroma, and overall quality. However, not all water is created equal, and brewers must contend with potential contaminants like chlorine and chloramine that can adversely affect the brewing process and the final product. In this lesson, we'll explore the impact of chlorine and chloramine in brewing water and why it's essential to prevent their presence when brewing beer.

Chlorine and chloramine are disinfectants commonly used in municipal water treatment to kill harmful bacteria and pathogens. While effective for ensuring safe drinking water, these chemicals can pose challenges for brewers. Chlorine is typically added directly to water as a disinfectant, while chloramine forms when ammonia is combined with chlorine. Both compounds can persist in water supplies and are not easily removed through boiling, making them particularly problematic for brewers.

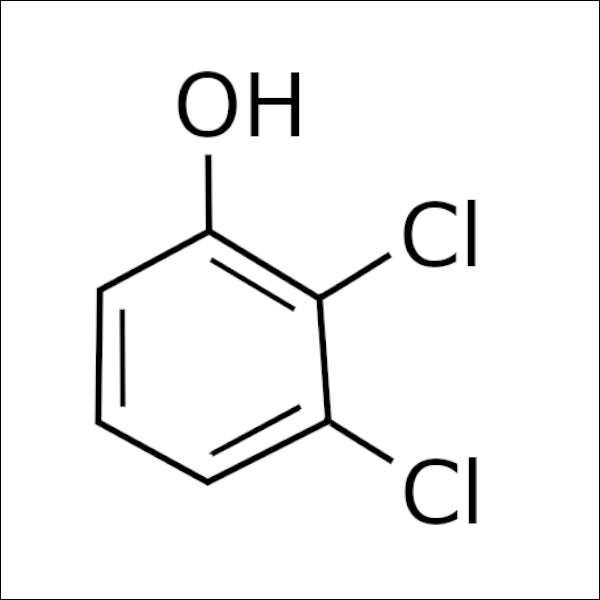

Chlorine and chloramine can have detrimental effects on beer flavor and aroma. When these chemicals react with organic compounds called "phenols" during the brewing process, it can form chlorophenols, which impart off-flavors described as medicinal, Band-Aid-like, or plastic-like, but is properly termed "chlorophenolic". This reaction is called "chlorination". Phenols are organic compounds characterized by a hydroxyl (-OH) group attached to an aromatic ring. In brewing, phenols are naturally present in malt and hops and contribute to beer's flavor and aroma. During the chlorination reaction, the chlorine or chloramine molecule replaces one of the hydrogen atoms on the phenolic ring, resulting in the formation of chlorophenols.

For you chemistry geeks, the general reaction mechanism can be represented as follows:

Phenol (C6H5OH) + Chlorine (Cl2) → Chlorophenol (C6H4ClOH) + Hydrochloric Acid (HCl)

or

Phenol (C6H5OH) + Chloramine (NH2Cl) → Chlorophenol (C6H4ClOH) + Ammonium Chloride (NH4Cl)

In these reactions, chlorine or chloramine substitutes for one of the hydrogen atoms on the phenolic ring, leading to the formation of chlorophenol and other byproducts like hydrochloric acid or ammonium chloride. These "chlorphenolic" off-flavors can mask the intended flavors of the beer and significantly detract from its overall quality and drinkability. Even at low concentrations, chlorophenols are detectable by the human palate and can ruin an otherwise well-crafted brew.

Prevention:

Preventing the presence of chlorine and chloramines in brewing water is a critical step for homebrewers to ensure the quality of their beer. These disinfectants can lead to the formation of chlorophenols, which can impart undesirable off-flavors and aromas to the finished product. To prevent the introduction of chlorine and chloramines into beer, homebrewers can take several proactive measures. By incorporating these prevention measures into their brewing practices, homebrewers can minimize the risk of chlorophenol formation and produce beer with clean, desirable flavors. Attention to water quality and sanitation is essential for maintaining the integrity and quality of homebrewed beer.

• Source Selection: Selecting an appropriate water source is essential. Choosing filtered water, spring water, or purchasing brewing water specifically designed for homebrewing can help minimize the presence of chlorine and chloramines. If tap water must be used, consider treating it to remove these disinfectants before brewing. NOTE: Refrain from using distilled water, or any other water with the minerals removed, unless you are adding those minerals back yourself. The yeast need these minerals to stay healthy during fermentation.

• Dechlorination: One common method of dechlorination is using campden tablets, which contain potassium metabisulfite. These tablets can neutralize chlorine and chloramines in brewing water when added according to the recommended dosage. Pre-treating brewing water with dechlorination agents before adding it to the mash or wort is advisable. This ensures that chlorine and chloramines are effectively neutralized before coming into contact with brewing ingredients, minimizing the risk of chlorophenol formation.

• Filtration: Filtration systems designed to remove chlorine and chloramine from water can be installed at the point of use, such as under the sink. These systems typically utilize activated carbon or catalytic carbon filters to adsorb chlorine and chloramine molecules.

• Boiling: While boiling water can remove chlorine, it is less effective at eliminating chloramine. Additionally, boiling large volumes of water can be time-consuming and energy-intensive, making it a less practical option for many brewers.

• Choose Your Cleaners Wisely: In addition to water treatment, maintaining proper sanitation practices is crucial. Using chlorine-free cleaners and sanitizers for brewing equipment and rinsing thoroughly with dechlorinated water helps prevent the introduction of chlorine-containing compounds during the brewing process.

• Test Your Water: Regular testing of brewing water for chlorine and chloramine levels can also provide valuable insight into the effectiveness of prevention methods. Homebrewers can use water testing kits or send samples to a laboratory for analysis to ensure that their water quality meets brewing standards. You can also contact your local water company to find out the chlorine/chloramine levels in the water (more on this in the Exercise section).

In the art of brewing, water quality is paramount. Chlorine and chloramine, common contaminants in municipal water supplies, can have profound effects on beer flavor and aroma, leading to off-flavors that detract from the overall drinking experience. By understanding the impact of these disinfectants and taking proactive measures to prevent their presence in brewing water, brewers can ensure the production of high-quality, flavorful beer that delights the palate and leaves a lasting impression.

Chlorophenol

Detecting Autolysis

Aroma:

• Medicinal: Reminiscent of medicinal products or antiseptics, often described as sharp, sterile, or reminiscent of a doctor's office.

• Band-Aid-Like: Similar to the smell of adhesive bandages or medical tape, with a distinct plasticky aroma.

• Plastic-Like: A synthetic aroma reminiscent of plastic or vinyl materials, often described as artificial or unnatural.

• Antiseptic: While not necessarily desirable in excess, autolysis can contribute subtle yeasty aromas, which are characteristic of certain beer styles.

• Chemical: Characterized by a strong, harsh chemical smell, reminiscent of laboratory chemicals or industrial solvents.

• Phenolic: Referring to compounds containing a phenol group, which can impart aromas of smoke, tar, or disinfectant-like qualities.

Flavor:

• Medicinal: Evokes the taste of cough syrup or antiseptic solutions, with a sharp, clinical flavor.

• Band-Aid-Like: Resembles the taste of adhesive bandages or medical tape, imparting a distinct plastic-like flavor.

• Plastic-Like: Conveys a synthetic taste akin to plastic or vinyl materials, giving the beer an artificial or unnatural flavor.

• Antiseptic: Tastes similar to disinfectant cleaners or antiseptic solutions, with a sharp, sterile flavor profile.

• Chemical: Exhibits a harsh, industrial taste reminiscent of laboratory chemicals or solvents, detracting from the beer's overall drinkability.

• Phenolic: Characterized by flavors of smoke, tar, or medicinal undertones, lending complexity but potentially overwhelming the palate.

These descriptions provide a nuanced understanding of the flavors associated with chlorophenolic compounds in beer, helping to identify and recognize these off-flavors during sensory evaluation.

Sensory Training:

• Educate Yourself: Learn about chlorophenols and their characteristics. Understand how they are formed in brewing, their chemical composition, and the off-flavors they impart to beer. Familiarize yourself with descriptions of chlorophenol off-flavors, such as medicinal, Band-Aid-like, or plastic-like.

• Use Reference Samples: If possible, obtain reference samples of beer intentionally contaminated with chlorophenols. These samples can be obtained from brewing laboratories or sensory analysis programs. Use these samples to train your palate to recognize the distinct off-flavors associated with chlorophenols.

• Contact Your Water Company: Most water municipalities provide regular water quality reports to their customers, which often include information about disinfectants such as chlorine or chloramines used in the treatment process. Additionally, you can contact your local water utility company directly to request specific information about chlorine levels in the water supply. Understanding the baseline levels of chlorine or chloramines in the water supply allows brewers to assess the potential impact on beer quality. By knowing the starting point, brewers can better anticipate the likelihood of chlorophenol formation during brewing.

• Targeted Training: Armed with knowledge of chlorine or chloramine levels, brewers can tailor their sensory training exercises to focus on detecting specific off-flavors associated with these chemicals. This targeted approach can help brewers develop a more acute sensitivity to chlorophenols in beer.

• Feedback Loop: Incorporating information about chlorine or chloramine levels into sensory evaluation sessions creates a feedback loop between water quality and beer quality. Brewers can correlate changes in water chemistry with sensory perceptions in beer, enhancing their understanding of how water treatment impacts beer flavor.

Overall, knowing the levels of chlorine or chloramines in the water supply empowers brewers to make informed decisions about water treatment and brewing practices, ultimately leading to better sensory perception of these chemicals in beer. By integrating water quality considerations into sensory training, brewers can refine their palates and produce high-quality beer with clean, desirable flavors.

Recommended Beers For This Lesson

Chlorophenols are most easily detected in light beers, especially pilners and lagers. These beers tend to benefit the most from clean, pure water since the flavors are more subtle than darker beers or hoppier beers. The beers below are great for brewing with a good clean water. Try comparing a batch made with tap water and a batch made with a clean spring water, and see if you can detect the differences. Just be sure to avoid distilled water since it lacks minerals the yeast and wort need.